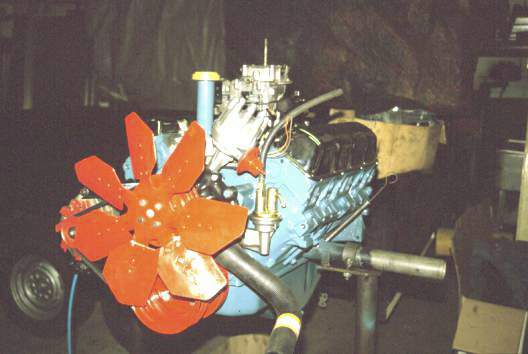

When I picked up my jeep, I first started to get it going again. After a couple of hours the engine started. The brakes were functioning so I could go for the testdrive. After a drive of approximately 3 miles I discovered that everything was functioning properly. The engine ran good, the oil pressure was okay (then ) and no strange sounds came from the engine or transmission, which also worked fine. I decided to take apart the jeep and clean and rebuild all the parts one by one, exept the engine and automatic transmission.